- Home

- Life Mel Range Full Presentation

Life Mel Range is a unique food supplements from the beehive, made by bees fed with a mixture of specially prepared Herbs.

One of the product, Life Mel Honey, was recently featured on ITV This Morning Show on 15th May'2018 where Dr. Chris Steele talked about LifeMel Honey and its benefits for the Cancer patients going through Chemotheraphy or Radiation Theraphy.

Life Mel Range consists of 14 different unique products, such as Life Mel Original (Chemotheraphy and Radiation Theraphy Support ) , Energy Mel, Relax Mel, Gastro Mel, Lady Mel Day and Lady Mel Night, Potent Mel, Magne Mel, Clear Mel, Vir Mel, Broncho Mel, Defence Mel, Laryngo Mel and Flor Mel.

The Life Mel Story begins with research in the 1970s by Dr. Alexander, then a med student, in a small town in Russia, beekeepers and their families remained healthy despite a local cholera epidemic.

Dr. Alexander spent his time working with experts to develop a method to feed the bees with the desired herb parts to facilitate the development of a honey bee product which contained the beneficial properties of a special blend of key herbs.

In the 1990s Dr. Alexander emigrated to Israel and with the help of state funding, continued his research into the remarkable results of feeding bees different selections of herbs. In time, he went on to develop different products made by honey bees. Nowadays, Dr. Alexander is an expert with apitherapy (the study of bee products for medical healing), a specialist in clinical microbiology, immunology and virology and serves to this day as the company Chief Scientist. Dr. Alexander has had numerous papers published in medical and scientific journals.

Over the years Dr. Alexander developed many types of therapeutic beehive products. Dr. Alexander continues to develop and produce many types of therapeutic beehive products. The company’s products are marketed in Israel, Europe, the United States, Canada and South Africa. The company intends to expand its activity to additional countries worldwide.

The company complies with all the standards required to manufacture nutritional supplements

I.S.O. By the Israeli standard institute | H.A.C.C.P Hazard Analysis Critical Control Point | G.M.P. Good Manufacturing Practice

Our unique process

In the preparation process of the food for the honeybees there is maximum strictness on the accurate amounts and ratio between the medicinal herbs.The formulas are a result of years of research and are exclusive to Zuf Globus Laboratories. Once the bees assimilate this mix, the unique process that goes on inside the hive results in a pure honey bee product that contains all the beneficial actives from the herbs in a greatly intensified form, offering key benefits which naturally assist a range of consumer health complaints.

This form of production ensures a full absorption of the active ingredients by the human body. The small intestine marks the second stage to the absorption process.

We therefore recommend that the dosage of all the products, with the exception of GastroMel, are placed under the tongue and sucked slowly to ensure complete absorption. We recommend to take the product on an empty stomach and not drinking for 20 minutes.

Manufacturing process

The first stage is to collect the parts of the medicinal plants that are needed for the specific product we want to produce. Most of these parts are not available for the bees in nature.

The second stage is to transfer the medicinal plants’ parts to a processing system.

After the medicinal herbs are processed, it is transferred to a special container to be mixed with sweet substances.

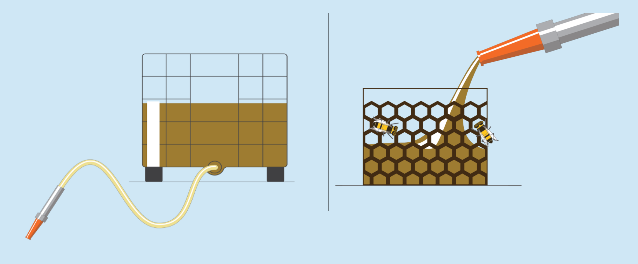

Honeybees will not consume food which is not tasty or that the bees suspect it may be harmful for their offspring.The ready bees food is filled into a 1M3 tank and taken by the beekeeper to the beehives, that are located in open fields.

A pipe used to fill the special feeding tank inside the beehive. The beekeeper fills the special feeding tank inside the beehive. The filling is repeated 16-24 times, every 2-4 days, until the bees seal the honeycomb.

After the honeybees seal the honeycomb, the beekeeper collects the beehive product and moves the final product, into barrels that go directly to Zuf Globus Laboratories. From each barrel a sample is taken, and sent to an independent laboratory in Germany, to confirm that there are no forbidden pollutants in the final product (such as pesticides, antibiotic etc.).

At the factory, the final product is filtered meticulously to get a product clean from any foreign bodies. The last stage is filling and labeling the jar.

Reasons why to choose Products

- 100% Natural

- Be innovative in your market place

- Our products are really effective and results are visible in short period of time

- High customer fidelity, once they try they will stick to our products

- Some products are unique, no competition with other existing products in the market

- We invest important part of our revenue in R&D clinical trials to acquire more products’s scientific evidence